Drawers are such a piece of cake.

Not for me of course. But in general, drawers are so cheap. You can buy the boxes on the internet for less than what it costs me to actually buy the materials. No joke, that’s real. Just google it. You’ll be stunned. Or maybe you won’t. After all, I’m a furniture making nerd, so the things that stun me are weird. Then you just screw your drawer face material to your internet made drawer box, and you’re in business. Fat city. It’s such a damn utilitarian thing, a drawer. You put the crap in it that you don’t want to have lying around, you close the drawer, and presto! Less clutter in your house. Also, from a fabrication perspective, drawer boxes are precisely the thing that plywood is perfect for. You need thin, strong, consistent swaths of material that can make, well, a box. With plywood you just cut out the shapes you need and join them together. With the right router jig, you can even make dovetails, and even fancier joinery.

But, and I bet you didn’t see this coming, it just doesn’t sit right with me. Drawers off the assembly line. pure function and efficiency over form. It’s this kind of thinking that has really kept me waltzing right around the poverty line for a good long time. It’s really hard to be an artisanal (dare I say artistic?) furniture maker and not make some bad decisions vis-a-vis price-to-product ratio.

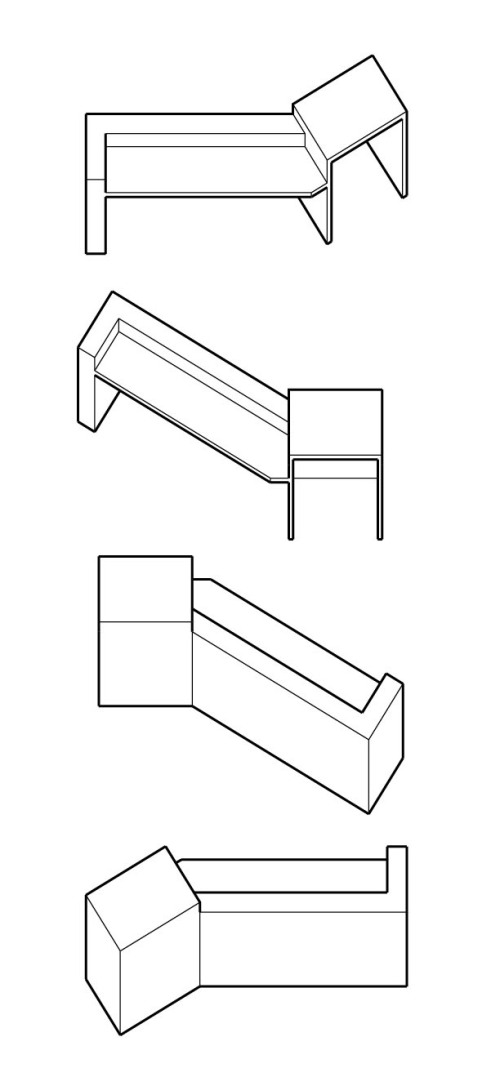

Drawer side and box joint jig.

See, if I was a good businessman, I’d be ruthlessly about my bottom line, and all else would fall into place from there. That’s not so hard to do when you’re going through your accounts, making your estimates, sourcing your materials, competing against a lousy economy for a job. But when you get in the damn shop, and you know you have to make the right choice to do better than break even, it’s not so simple. It’s hard to automate instead of express. Inevitably (and I should really know myself by now) I choose to do what I see as the right thing artistically at the expense of the bottom line.

Witness, the chest of drawers I’m currently building.

- A stack of box-jointed solid wood drawers

I love making these box jointed drawers. But I can never pay for them. They’re solid wood everywhere, including in the bottom, where you could so easily hide plywood. They’re so much harder to install, because you can’t use an applied face to cover your mistakes. The face of the drawer is the front of the box. Period. But I also can’t help but believe that they are nicer for it. I feel better making them. I just can’t take you out to dinner with the proceeds. Thanks for understanding.

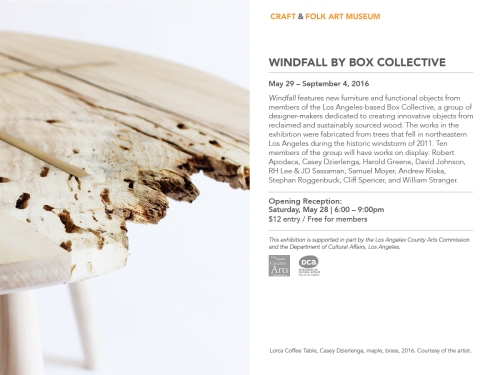

Cradle type base for the chest of drawers I’m making. In ze glue up phase. I got that massive clamp at the San Bernardino flea market for a dollar. I love that thing.

my main assistant, and primary counselor, hard at work on her chew toy.